qmtachage-100

Equipment for measuring the depth of anchor penetration into the escape wheel

Equipment for measuring the depth of anchor penetration into the escape wheel

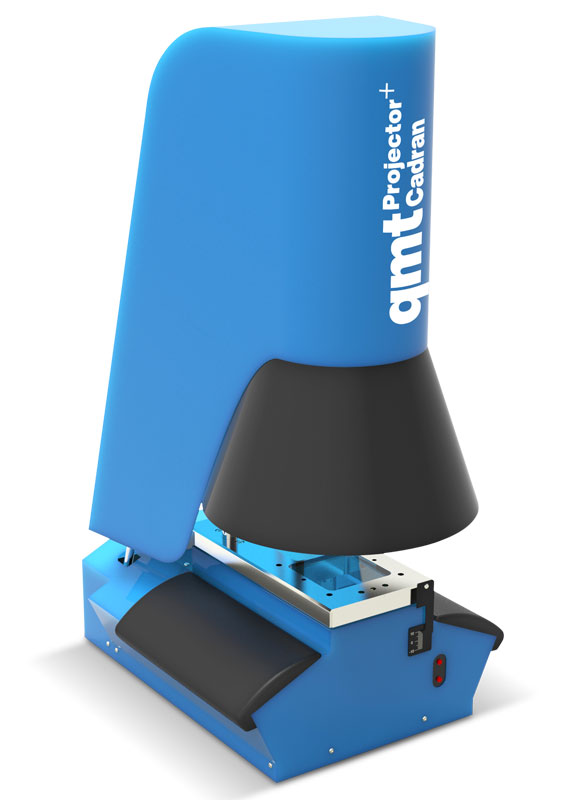

The qmtachepage-100 is a state-of-the-art optical instrument specifically designed to measure the geometric characteristics of the escapement related to the finishing process. It allows for the measurement of penetration depths and roundness.

A pneumatic actuation system enables measurement of movements without an oscillator. It is fully integrated and compact; optionally, computer hardware can also be integrated.

The optical system of the qmtachepage-100 allows for the simultaneous measurement of both anchor pallets with high precision and high speed. This makes it possible to perform measurements in static conditions (movement without an oscillator with pneumatic actuation) and in dynamic conditions (functional movement with an oscillator).

The qmtachepage software was specifically developed for this equipment; it is very easy to use both for taking measurements and for creating measurement programs.

- Cycle time less than 15 seconds with simultaneous measurement of both pallets

- Accuracy and measurement capability with a high-resolution telecentric optical system and pneumatic actuation control

- Integrated and compact equipment

- Connectivity capability for transferring data to other systems

Customizable solutions to perfectly meet your needs

measure

Tailor-made solutions designed to meet specific requirements

Tailor-made solutionsTools

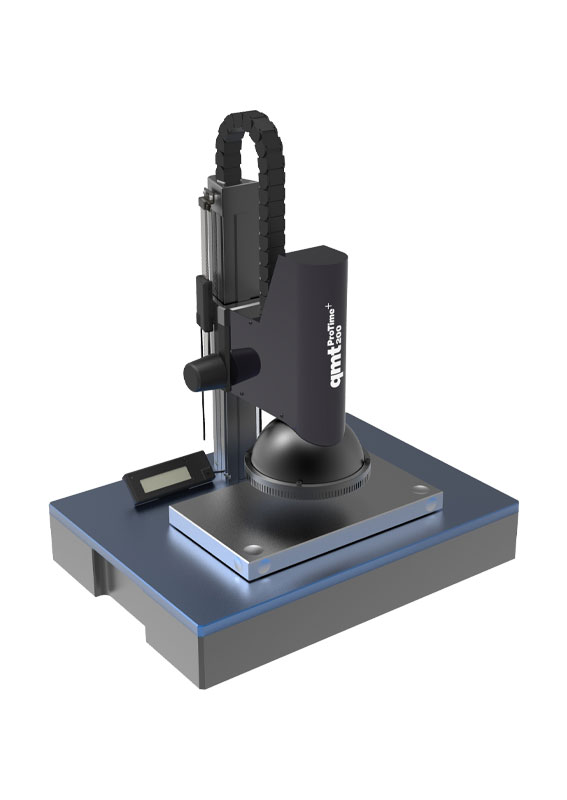

Communication of qmtachevage-100 measurements to VOH IV

In order to facilitate adjustment operations, the interfacing of the two pieces of equipment was carried out via LINKiX communication: the correction value is transmitted between the measuring device (the qmtachevage-100) and the correction device (VOH IV) automatically. Among the information transmitted are the manufacturing order and the identification of the movement, in addition to the entry and exit correction of the lift to be carried out

readingThe measurement of the exhaust

QMTachetage-100 technologies

The qmtachepage-100 is a device for measuring the depth of anchor penetration into the escape wheel of movements.

The qmtachepage-100 offers two measurement modes. The static mode with anchor actuation by a pneumatic system (movement without oscillator), the dynamic mode with measurement performed by high-speed acquisition with automatic image detection showing total engagement.

The qmtachepage-100 is fully integrated with a small footprint (560 x 210 x 350). It only requires power (electricity and compressed air) to be operational.

An 8MP camera (2800 x 2800 pixels) and a 5.4 x 5.4mm telecentric lens

The optical system allows simultaneous measurement of the input and output paddles for a measurement on a single revolution of the escape wheel and a cycle time of < 15 seconds

Customization for advanced management such as automatic sending of results to databases

The client can choose the IT equipment to best meet their needs and standards, either equipment integrated by QMT or their own equipment.

Compact and integrated with speed and measurement accuracy

| Basic functions and performance | Options | |

|---|---|---|

| Available measurements |

| Measurement of movements where the view of the anchor and the pallet is not through-hole, with multi-sector episcopic lighting |

| Precision [μm] | 1 | Multi-revolution measurement function for improved measurement accuracy and to account for pallet masking by moving components |

| Characteristics of measurable calibers | All calibers where both paddles are within a 5.2 x 5.2 mm area, have openings to view the paddles, and a maximum frequency of 5Hz (dynamic mode) | Whirlpool cage |

| Measurement methods |

| |

| Actuation | Pneumatic with controlled pressure regulation according to the item's settings | Specific actuation for measuring vortex cages |

| Time for a measurement in pneumatically actuated mode [s] | 15 seconds for a measurement over one revolution of the input and output pallets (simultaneous measurement of both pallets) | |

| Tools | Tooling incorporating actuation nozzles with guaranteed positioning |

|

| Software | Specific software qmtachage

|

|

| Creation and management of measurement programs |

| Centralized program management on a server for use by multiple devices |

| Verification and calibration | To be defined | Calibration and preventive maintenance performed by QMT |

| Computer science | IT equipment delivered by the customer |

|

| Dimensions (H x W x D) [mm] | 560 x 210 x 350 | |

| Item codes | AQ021AA001 |

All solutions are based on unique software functions

For optical control

To increase production yields

and the quality of the parts

For aesthetic control

For acoustic and vibration control